TEC Temperature Controllers, Precision Temperature Control, Precision Temperature Control, Temperature Control Modules, Thermoelectric Cooling, High and Low Temperature Control, PID Temperature Control, Constant Temperature Control System, Multi-channel Temperature Controllers, Temperature Closed-Loop Control, Temperature Stability, Temperature Drivers, Laboratory Temperature Control, Industrial Temperature Control Systems, Optical Module Temperature Control, Chip Testing Temperature Control, Semiconductor Temperature Control, Battery Testing Temperature Control, Optical Aging Testing, Panel Hot Plate Oven Temperature Control, Lithium Battery Temperature Controllers, Temperature Control Solutions, Optical Communication Device Temperature Control, Optical Lens Aging Testing, High-Speed Optical Module Temperature Control, Optical Module Aging Verification, Chip FT Testing Temperature Control, Chip Aging Testing, Temperature Drift Suppression, Constant Temperature Hot Plate Control, Wafer Probe Station Temperature Control, ATE Testing Temperature Control, Wafer Testing Platform Temperature Control, Semiconductor Mass Production Temperature Control, TEC Temperature Control Platform, High-Precision Temperature Control Equipment, Temperature Control Closed-Loop System, Temperature Controller, Optoelectronic Device Temperature Control, Battery Aging Line Temperature Control, Optical Module Bit Error Rate Tester Temperature Control, Battery Charge and Discharge Temperature Control, Optical Module High and Low Temperature Testing, Optical Module Temperature Control Stability, Optical Module Temperature Closed-Loop, Semiconductor Laboratory Temperature Control, Battery Module Temperature Control Optical component durability testing; semiconductor packaging temperature control; TEC temperature control module; optical module reliability verification; wafer-level temperature control; semiconductor R&D temperature control; industrial precision temperature control system.

News

News

Update Time:2025-12-11 11:33:41

Update Time:2025-12-11 11:33:41 Views:536

Views:536

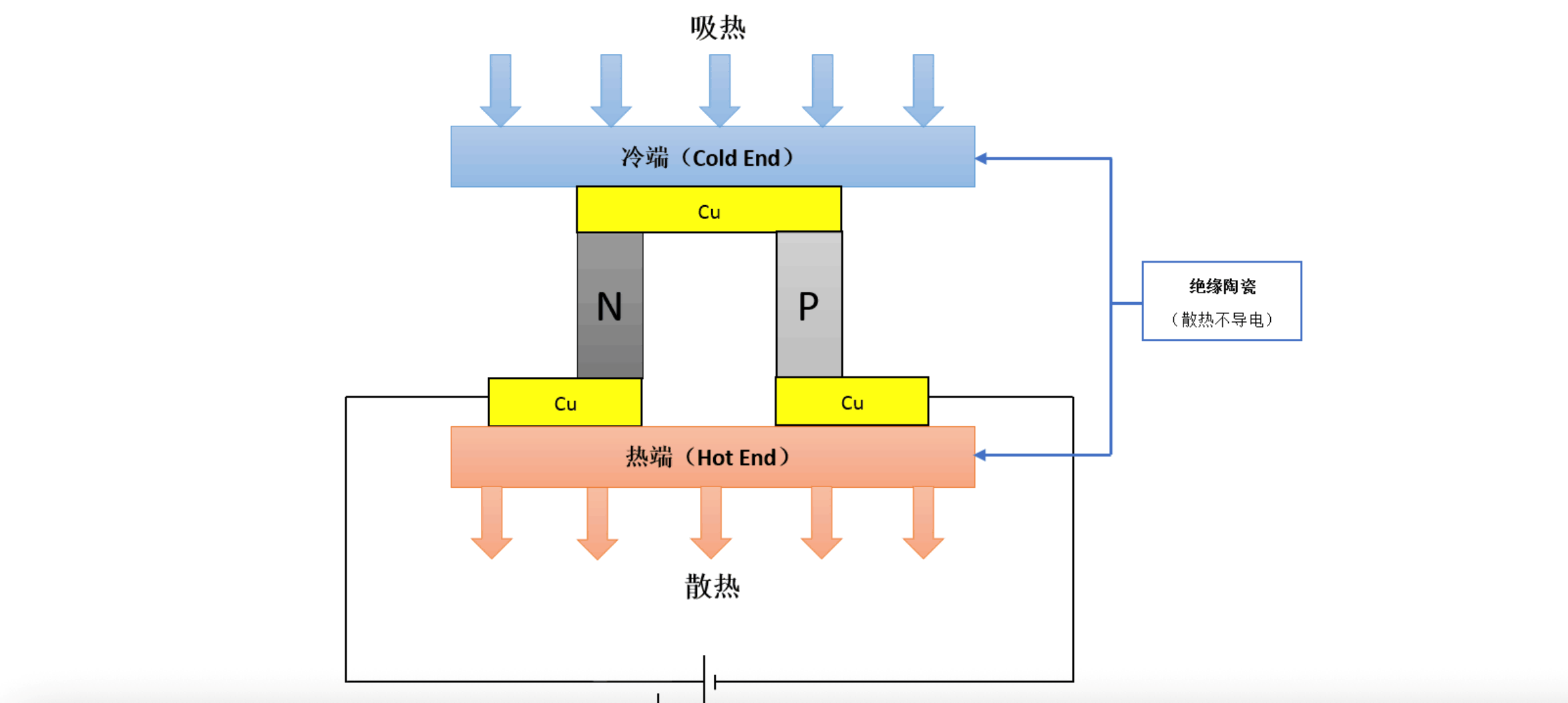

TEC (Thermoelectric Cooler) semiconductor coolers achieve cooling or heating through the Peltier effect—requiring no compressor or refrigerant, only electricity. With their small size, low noise, and ease of integration, they have become an indispensable temperature control method for modern precision equipment. However, a TEC cooler alone is insufficient to meet requirements such as "precise temperature control, automatic start/stop, stable temperature control, and system protection." To address this issue, BlueGuard has launched a series of temperature controllers—using sensors, drive modules, and PID control algorithms to achieve real-time monitoring and precise temperature control. They also feature multiple safety mechanisms, including over-temperature protection, short-circuit protection, current overload protection, and sensor anomaly detection, comprehensively improving system reliability and stability.

Equipment Overview

The TEC TTD70xx series temperature controller is a highly integrated temperature control device that combines temperature acquisition and bidirectional DC temperature output. It can directly drive DC loads (such as TEC cooling coils), eliminating the need for external data acquisition units and solid-state relays. Based on real-time temperature data (PV) and the user-defined target temperature (SV), the controller intelligently calculates the PID control ratio and intelligently adjusts the output of cooling/heating power devices using PWM to achieve precise temperature control. Furthermore, the device is equipped with a 100Mbps high-speed network interface for easy connection to a host computer, supporting the standard Modbus TCP/RTU communication protocol to ensure efficient and compatible data transmission. The device features precise temperature control, high stability, strong anti-interference capabilities, and multi-level over-temperature protection. The system includes functions such as stopping output upon over-temperature alarm and shutting down output upon exceeding temperature limits, effectively protecting the safety of controlled items.

Equipment Model List:

| 序号 | 名称 | 型号 | 说明 |

|---|---|---|---|

| 1 | TEC温控器 | TTD7002 | Integrated with 2-channel NTC temperature acquisition and 2-channel 15A DC bidirectional load output (TEC cooling chip). Uplink 100M Ethernet Modbus TCP protocol communication; screw-mounted installation. |

| 2 | TEC温控器 | TTD7004 | Integrated 84-channel NTC temperature acquisition, 4-channel 15A DC bidirectional load output (TEC cooling chip). Uplink 100M Ethernet Modbus TCP protocol communication, screw-mounted installation. |

| 3 | TEC温控器 | TTD7008 | Integrated 8-channel NTC temperature acquisition, 8-channel 10A DC bidirectional load output (TEC cooling chip). Uplink 100M Ethernet Modbus TCP protocol communication, screw-mounted installation. |

Equipment Features

3.1 Industrial-Grade Design

⚫ High-performance industrial-grade 32-bit processor

⚫ Supports long-term stable operation from -20°C to 65°C

⚫ Aluminum alloy casing, resistant to electromagnetic interference

3.2 Reliability and Stability

⚫ Watchdog design ensures long-term stable system operation

⚫ Comprehensive protection mechanism ensures equipment stability

⚫ Built-in surge and electrostatic protection for power input interface

⚫ Reverse connection protection for input power interface, short-circuit protection for load output channel

3.3 Product Usability

⚫ Plug-and-play interface for easy temperature acquisition and maintenance

⚫ Supports plug-and-play, no complex configuration required

⚫ Communication uses standard Modbus TCP/RTU protocol

⚫ Type-C interface on the front of the main unit for easy debugging

⚫ Supports host computer software (TSC) configuration management

3.4 Product Features

⚫ Supports 2/4/8-channel NTC temperature acquisition (range -60~150℃)

⚫ Supports 2/4/8-channel DC bidirectional control output (directly drives TEC cooling coils for heating or cooling)

⚫ Supports Modbus TCP/RTU standard protocol, supporting function codes 01, 03, 05, 06, 15, and 16

⚫ 100M Ethernet uplink communication for the temperature controller

⚫ Integrated multi-channel design for temperature acquisition and control

⚫ Open PID parameter settings for the temperature controller, supporting independent PID for each channel, with self-tuning function

⚫ Multiple over-temperature protection mechanisms, load output open-circuit alarm, and short-circuit protection functions

⚫ Temperature control accuracy: ≤±0.1℃, resolution: 0.01℃

BlueGuard's integrated temperature control solution

Through the newly released multi-series TEC temperature controllers, BlueGuard temperature control will bring higher temperature control efficiency and system reliability to semiconductor manufacturing, optical communication, laser cooling, medical equipment, scientific research and testing, and other fields—helping customers cope with diverse and demanding temperature control challenges. Customized support and professional services can be provided according to customers' actual application scenarios and needs to achieve the goal of "high-efficiency cooling + precise temperature control + stable reliability".

Guangzhou Lanweishi is a high-tech enterprise specializing in industrial temperature control, automation control, and information system integration. It is committed to providing precise temperature control, environmental monitoring, and industrial data interconnection solutions for industries such as optoelectronic manufacturing, semiconductors, thermal equipment, new energy, rubber and plastics, and scientific research institutions.

Guangzhou Lanweishi is a high-tech enterprise specializing in industrial temperature control, automation control, and information system integration. It is committed to providing precise temperature control, environmental monitoring, and industrial data interconnection solutions for industries such as optoelectronic manufacturing, semiconductors, thermal equipment, new energy, rubber and plastics, and scientific research institutions.

With the mission of "Intelligent Temperature Control, Making Industry More Efficient and Safe," the company provides customers with a series of temperature control products featuring high-precision data acquisition and intelligent control algorithms. These products include modular temperature controllers, TEC temperature controllers, integrated temperature controllers, power regulators, I/O acquisition modules, protocol gateways, and host computer software platforms.

Adhering to the philosophy of "Winning Trust with Technology, Building a Brand with Quality," the company strictly implements the ISO quality management system, and its products have obtained international certifications such as CE, FCC, and RoHS. With stable and reliable control performance and comprehensive technical support services, Lanweishi's temperature control products have been widely used in various industries, including optoelectronic manufacturing, semiconductors, thermal equipment, new energy, and rubber and plastics.

In the future, Guangzhou Blue Guard will continue to focus on intelligent control and industrial internet technology innovation, creating a full-stack solution centered on "temperature control + data acquisition + communication + software platform" to help manufacturing customers achieve intelligent production and energy efficiency.

Email: 616526410@qq.com

Hotline: 13609016130

Address: Room 314, 3rd Floor, No. 9, Kemulang South Road, Tianhe District, Guangzhou

Filing No.: 粤ICP备2023092377号-3

Products

Temperature controller

Temperature controller  Temperature acquisition device

Temperature acquisition device  Industrial I/O Modules

Industrial I/O Modules  Industrial gateway

Industrial gateway  Power Regulator

Power Regulator Solutions

Semiconductor/Chip Industry

Semiconductor/Chip Industry  New energy/energy storage industry

New energy/energy storage industry  Optoelectronics/Display Industry

Optoelectronics/Display Industry  Rubber/Plastics Industry

Rubber/Plastics Industry  Biopharmaceutical industry

Biopharmaceutical industry  Industrial Furnaces/Thermal Industry

Industrial Furnaces/Thermal Industry  Mechanical Automation Industry

Mechanical Automation Industry  Other integrated applications

Other integrated applications Support

Manuals

Manuals

Tutorials

Tutorials

Tools

Tools

News

Company News

Company News  Exhibition News

Exhibition News  Media Information

Media Information