Guangzhou Lanweishi (Blue Guardian) - Lanweishi Temperature Controllers, Lanweishi Temperature Control, LCD Panel Hot Plate Oven Temperature Controllers, Hot Plate Oven Temperature Control, Precision Temperature Control, Hot Plate Oven Constant Temperature, Closed-Loop Temperature Control, Panel Heating Temperature Control, LCD Process Temperature Control, PID Temperature Control, Hot Plate Oven Heating Section Temperature Control, Temperature Curve Control, Multi-Channel Temperature Controllers, Panel Aging Testing, Temperature Stability Control, Panel Molding Temperature Control, Integrated Heating and Cooling Temperature Control, Industrial Temperature Control Systems, Hot Plate Temperature Management, Hot Plate Oven Process Temperature Control, High-Precision Temperature Control Equipment

News

News

Update Time:2025-12-11 14:56:27

Update Time:2025-12-11 14:56:27 Views:

643

Views:

643 Background Introduction

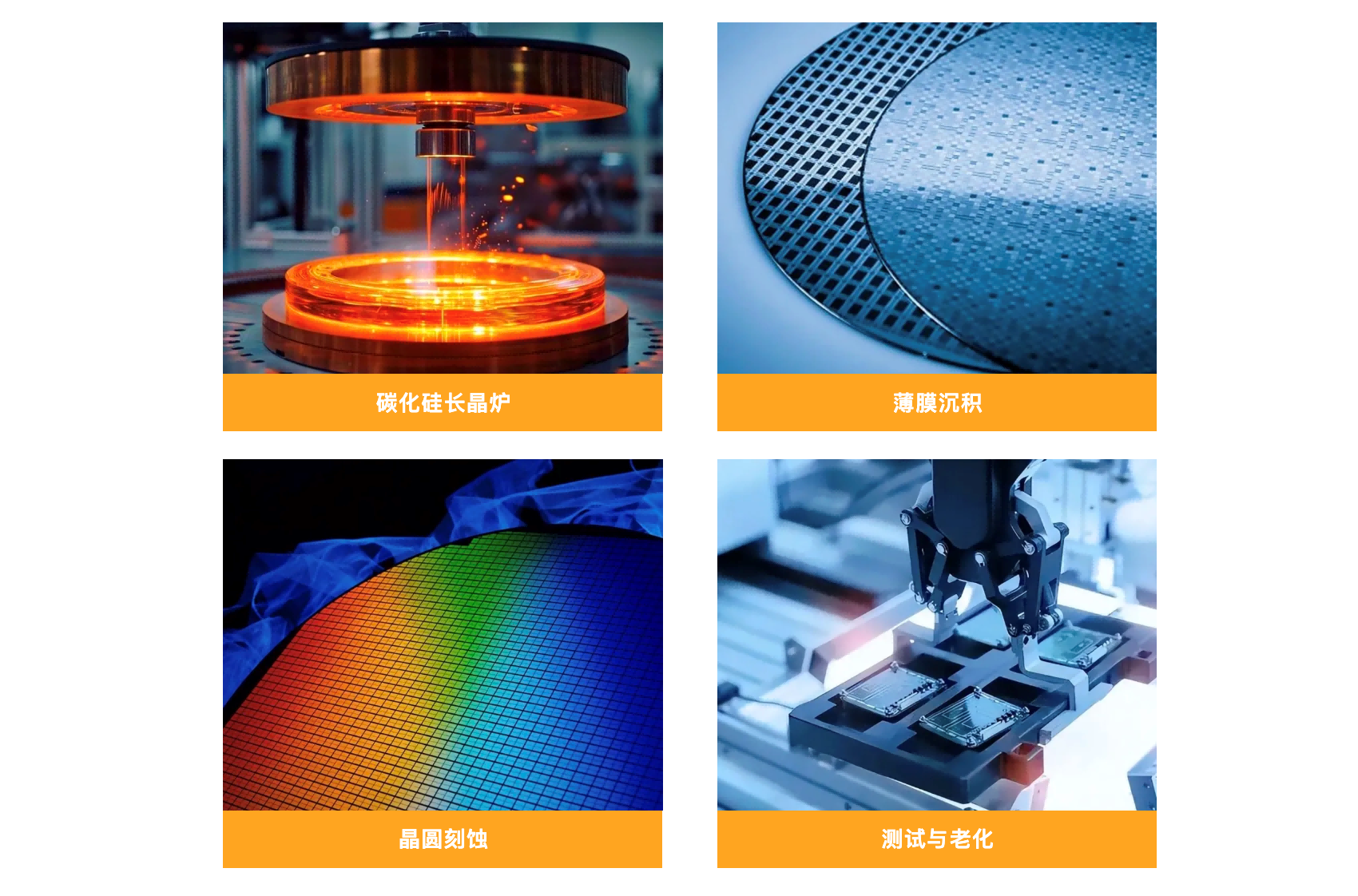

Hot plate furnaces are key equipment in semiconductor manufacturing used for pre-treatment baking of materials such as silicon wafers, gallium arsenide, and glass panels before adhesive coating. Their core function is to simultaneously and efficiently heat multiple semiconductor wafers through a heating mechanism.

01 Solution Introduction

High-Precision, Scalable Temperature Control System

The TMA modular temperature controller provides multi-channel temperature acquisition and heating control, which can be flexibly combined according to the temperature control requirements of different areas of the hot plate furnace to form a high-precision, scalable temperature control system.

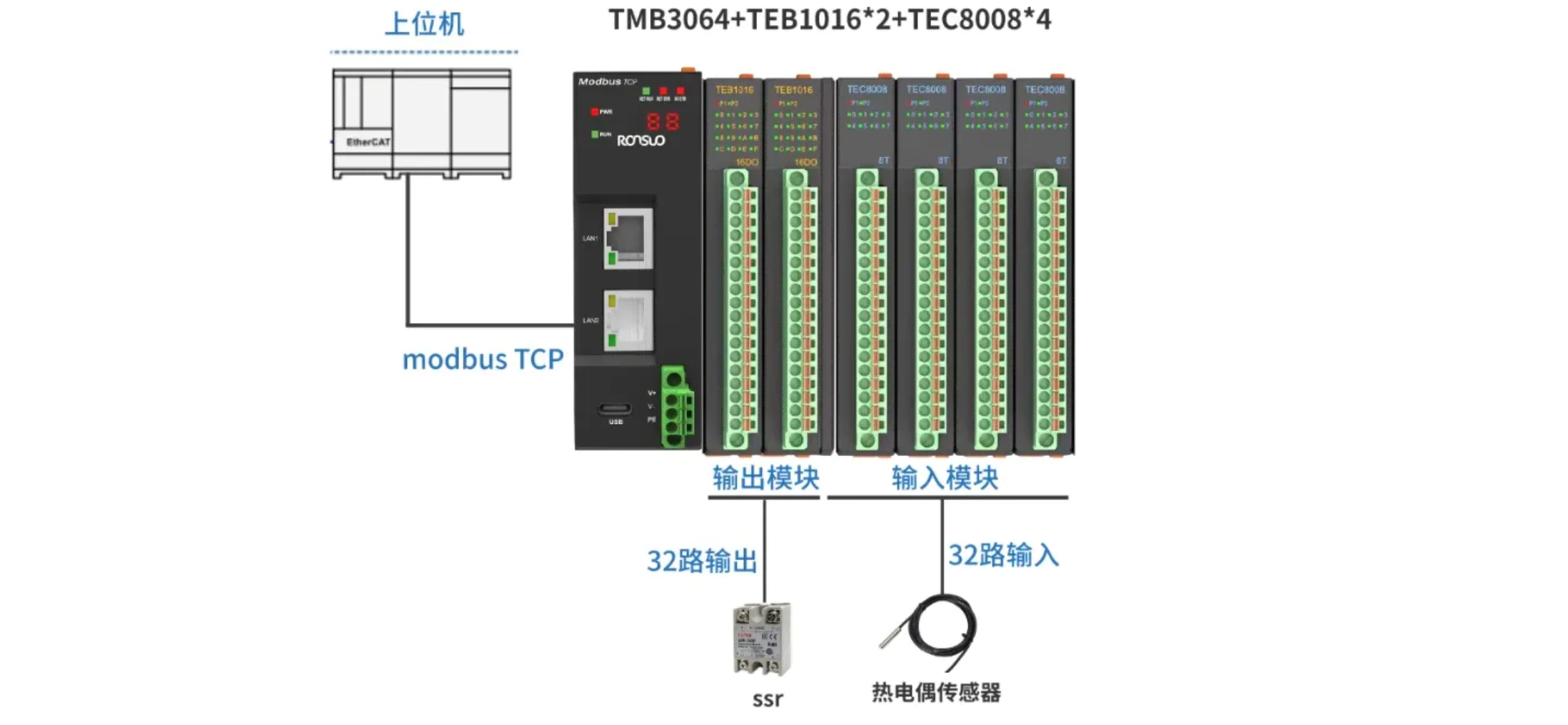

02 Solution Topology Diagram

TMB Temperature Controller Main Unit + TEB Output Module + TEC Input Module

32-channel temperature acquisition (thermocouple, PT100, etc.)

32-channel heating control output (SSR/relay drive)

PID intelligent algorithm for precise temperature control

Supports industrial communication protocols such as RS485 and TCP/IP

Modular expansion for flexible adaptation to different hot plate sizes and heating areas

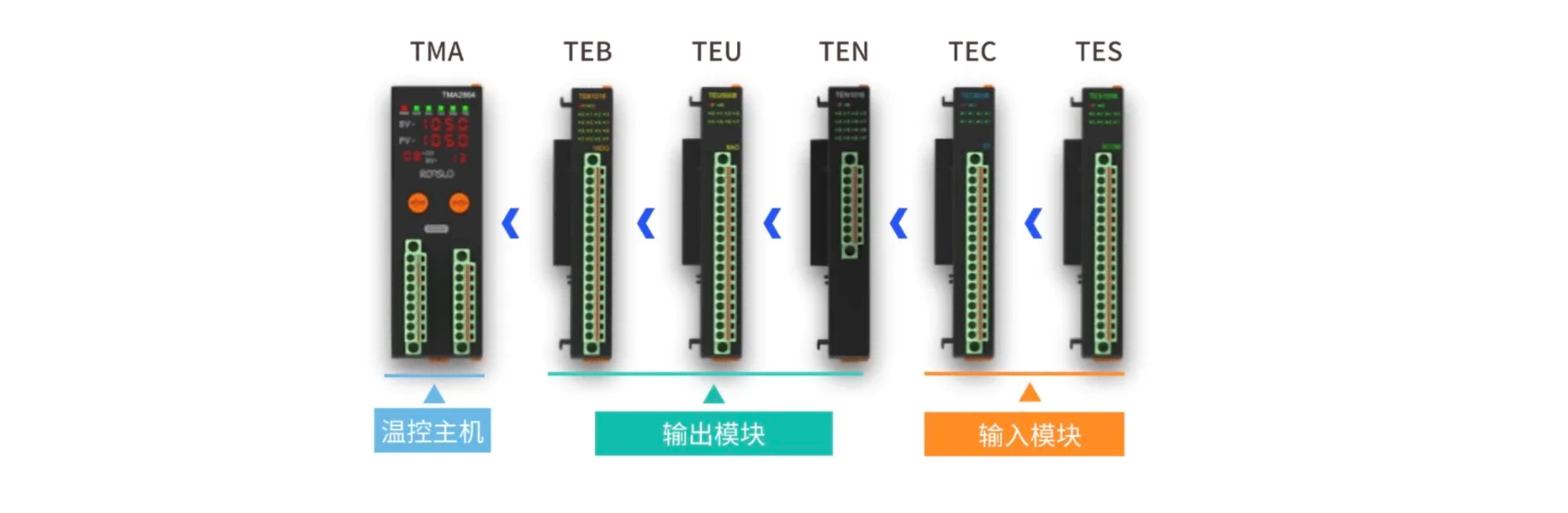

Combined temperature controller

Modular design, flexible configuration, meets diverse temperature control needs

A wide range of product models are available, with up to 64 outputs and 192 inputs expandable.

News

News

Email: 616526410@qq.com

Hotline: 13609016130

Address: Room 314, 3rd Floor, No. 9, Kemulang South Road, Tianhe District, Guangzhou

Filing No.: 粤ICP备2023092377号-3

Products

Temperature controller

Temperature controller  Temperature acquisition device

Temperature acquisition device  Industrial I/O Modules

Industrial I/O Modules  Industrial gateway

Industrial gateway  Power Regulator

Power Regulator Solutions

Semiconductor/Chip Industry

Semiconductor/Chip Industry  New energy/energy storage industry

New energy/energy storage industry  Optoelectronics/Display Industry

Optoelectronics/Display Industry  Rubber/Plastics Industry

Rubber/Plastics Industry  Biopharmaceutical industry

Biopharmaceutical industry  Industrial Furnaces/Thermal Industry

Industrial Furnaces/Thermal Industry  Mechanical Automation Industry

Mechanical Automation Industry  Other integrated applications

Other integrated applications Support

Manuals

Manuals

Tutorials

Tutorials

Tools

Tools

News

Company News

Company News  Exhibition News

Exhibition News  Media Information

Media Information